|

Cut 3.0D

Software – Features

1. 3D Model Formats

Cut3D includes powerful import

filters that work with most of the industry standard mesh file formats.

3D CAD and Graphics Design

software packages will typically include standard options for saving 3D

models in at least one of the file formats supported by Cut3D. The

commonly used design software products are,

a. Rhino3D

b. 3D Studio

c. AutoCAD

d. Bobcad

e. ProEngineer

f. Solid Works

g. SolidEdge

h. Silo

The internet is

a very useful source for 3D models with many web sites offering 3D

clipart pieces. Many of these also offer Free models that can be used to

test they work with Cut3D.

The 3D file types supported in Cut3D

are

|

STL |

|

STL

Mesh files - binary & ascii |

|

3DS |

|

3D

Studio - binary & ascii |

|

DXF |

|

AutoCAD 3D DXF |

|

OBJ |

|

Wavefront |

|

SBP |

|

ShopBot Digital Probe files |

|

TXT |

|

MaxNC Digital Probe |

|

WRL |

|

VRML |

|

X |

|

DirectX |

|

LWO |

|

LightWave |

|

V3M |

|

Vector Art 3D files |

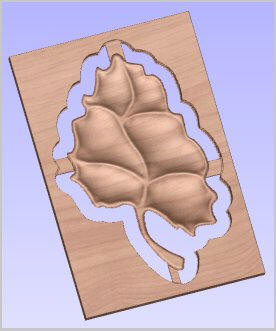

2.

Sizing and Positioning

3D Models are typically designed

in any orientation and at any size. Cut3D includes options for selecting

what faces of the model to machine, mirroring, rotating and setting the

required size in Inches or Metric.

Multi-sided

Machining

3D models can be machined as

single, double or four sided projects. Simply select the option required

and Cut3D calculates the all of the associated toolpaths automatically!

3. Automatic Boundary detection with Tabs

Automatic Boundary Detection

When cutting 3D

projects it's important to minimize the machining times by not wasting

time cutting unwanted regions of the material. Cut3D includes a unique

option for detecting the model boundaries and limiting the toolpaths

inside these regions.

Interactive

Tab Placement

When cutting models completely

out of the material it's essential to have tabs to stop the job breaking

free during machining.

4. Fast and Efficient 3D Toolpath Options

Roughing

Toolpaths

Fast and efficient Z Level rough

machining removes unwanted stock material quickly and easily, leaving

material on the model for the Finishing toolpath to remove.

Finishing

toolpaths

High quality 3D finishing

cutterpaths are calculated in seconds.

Cut Out

toolpath

Once the model has been machined

to the required size it can easily be cut out of the material using the

Cut Out toolpath. This option automatically calculates the boundary

silhouette and calculates a multiple z level profile toolpath to cut

around the shape.

5. Model Slicing

When a 3D model is to large /

thick to fit under the gantry on your machine or you don't have thick

enough material, the model can very easily be 'sliced' into thinner

sections. For example, a 24" high model can be sliced into 12 x 2" thick

pieces that can then be machined and assembled.

6. Realistic Toolpath Preview

The calculated toolpaths can be

simulated into different materials to show exactly what they will

produce when run on the CNC machine.

7. Estimated machining times

Cut3D automatically calculates

the theoretical cutting times for each of the toolpaths using the

specified feed rates.

8. Saving the toolpaths

Standard postprocessor's are

included for virtually all CNC machine control systems. The

postprocessor's are 'open' and can easily be configured to match

specific file formats.

The

postprocessor supports Automatic Tool Changing and can easily be

modified to save the roughing, finishing and cut out toolpaths into a

single file. |