CONTACT US

Panamech Machinery Sdn Bhd

NO.14, LORONG SANGGUL 1C,

BANDAR PUTERI,

41200 KLANG,

SELANGOR DARUL EHSAN,

MALAYSIA.

Tel: 03-51617876/ 03-51618036

Fax: 03-51617136

Email:

info@panamech.com.my

Panamech (Penang) Sdn Bhd

SRI RELAU COMPLEX, UNIT 1-3-11,

PERSIARAN BUKIT JAMBUL 1,

11900 PENANG,

MALAYSIA.

Tel: 04-6451635 / 6438266

Fax: 04-6451639

|

|

|

PROMA CNC ICV 4030

|

|

Made in Germany |

The Basic Machine will consist of the

items followings:-

a. Controller IMD-10 with integrated PC w/o monitor

b. EdiTasc Real time Controller/Operating Software

c. DC Servo motor 120V

d. DC Spindle Motor 500W c//w 1 pc of collet dia.6.0mm

e. CAM Software

f. Nut strips

g. Hand Level Clamping Device 2 pcs

Furthermore, the basic machine can be match optionally with accessories

below:-

a. Length measuring switch |

Highlights of the ICV 4030

Design

The ICV 4030 is a compact servo motor machine which is the very

small foot print and its specially conceived for quick 3D applications

in mould making respectively Rapid Prototyping.

The complete control and power electronic is

integrated in the back wall of the chassis. As a consequence of the

completely bolted chassis higher precision is the result of the

structure of the machine as well as an improved ease of servicing

compared to the welded chassis of the CPM series. Furthermore the

resonance and vibration behavior could be optimized and thus a smaller

noise development be achieved.

Furthermore, it have sliding door as safety enclosure. The upward

opening sliding hood can now be

operated comfortably from sitting position. By the lock of the

protection cover during milling all relevant CE safety standards are

ensured.

This singular and modern Plug & Play control concept could be done

without unnecessary PC board in the control PC. Plug & Play-PC control

by Windows with USB communication interface. There are no additionally

PC slot-in card necessary.

|

Drive Control

The ICV 4030 comes with a Controller IMD-10 with integrated Win

XP PC w/o monitor. Thus, the power electronics is thereby integrated in

housing and is connected to the control computer by the parallel

interface. Hence, the positioning control itself is realized by means of

the EdiTasc Real time Controller/Operating Software.

Software

The ICV 4030 is by default shipped with a basic version of the

EdiTasc Real time Controller/Operating Software

and CAM software. By the way, other optional NC software products like

the Isy CAD/CAM 3.0D, ProNC or Galaad can be used by exchanging the

positioning control. Furthermore, various import filters e.g. for HPGL

data, DXF files or Corel files ensure a universal data exchange. |

|

|

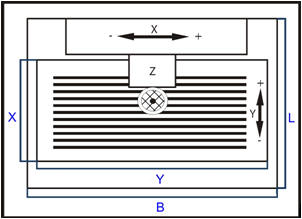

General Technical Data |

|

Model |

ICV 4030 |

|

Machine

dimensions |

780 x 850 x

810mm |

|

Machine

weight |

150 kg |

|

Milling table

dimensions |

600 x 375 mm |

|

XYZ-axis

travels |

400 x 300 x

110mm |

|

Z-Axis head

room |

150 mm |

|

Repeating

accuracy |

+/- 0.02 mm |

|

Resolution |

0.01 mm |

|

Travel feed

rate |

80

mm/s

|

|

Spindle motor |

DC 500W |

|

Linear Guides |

Play-free

precision steal shaft guides |

|

Drive system |

DC Servo

motor |

|

Controller |

Controller

IMD-10 with intergrated Win XP PC w/o monitor |

|

Operating

software |

EdiTasc (realtime

software) for the parallel interface |

Dimensions

|

|

Application

ICV 4030 |

Cylindrical surface machining

Professional engraving

Rapid-prototyping

Milling of 3D-design models

Multi-side machining |

|

|

|

|

|

|

3D MODEL |

EASY DIE |

WAX |

3D FIGURE |

ARICHTECTURE MODELZ |

|

Typical materials for machining |

Milling plastics

Plastics

Non ferrous

Wood

Foam

|

|

|