CONTACT US

Panamech Machinery Sdn Bhd

NO.14, LORONG SANGGUL 1C,

BANDAR PUTERI,

41200 KLANG,

SELANGOR DARUL EHSAN,

MALAYSIA.

Tel: 03-51617876/ 03-51618036

Fax: 03-51617136

Email:

info@panamech.com.my

Panamech (Penang) Sdn Bhd

SRI RELAU COMPLEX, UNIT 1-3-11,

PERSIARAN BUKIT JAMBUL 1,

11900 PENANG,

MALAYSIA.

Tel: 04-6451635 / 6438266

Fax: 04-6451639

|

|

|

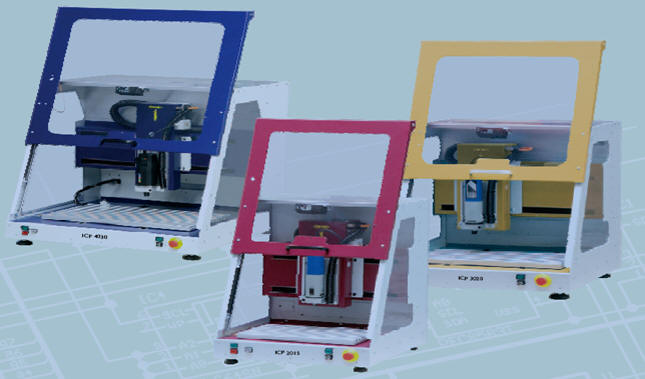

ICP-Series

2015/3020/4030 |

MADE IN GERMANY

|

The

Basic Machine consist of the items followings:-

a. Intergrated 4-axis microstep stepper motor controller, RS 232

communication interface

b. Editasc Controller / Operating Software

c. CAM Software

d. DC Spindle Motor UFM (500W / 1050W) c/w 1 pc of collet Dia.6.0m

e. Hand Level Clamping Device

2pcs

f. Nut strips 2pcs

Furthermore, the basic machine can be match

optionally with accessories below:-

a. 2-in-1 Engraving spindle c/w Attachment plate

|

Highlights of the ICP Series 2015/3020/4030

Design

ICP series are "ready to use" 3D-capable machines that suitable for

industrial use as well as for education purposes. The integrated 4-axis

stepper motor control RS232 makes possible a good movement by the

microstep mode.

The machines are appropriate for machining wood, plastics, light metals,

printed circuit boards, etc. and with an extensive range of accessories

applicable in many ways.

The ICP series have Safety circuit and emergency stop are

standard. The new design allows space-saving use with optimum ease of

operation. The sliding doors opening upwards can be actuated by the

operator even when sitting Greater efficency, conveniance and precision

by means of this new construction.

Drive Control

ICP series comes with a compact three-axis drive control. The

power electronics is thereby integrated in housing and is connected to

the control computer by the parallel interface. The positioning control

itself is realized by means of the EdiTasc realtime software.

Software

ICP series is by default shipped with a basic version of the

Controller/Operating software EdiTasc. Other optional NC software

products like the is CAD/CAM 2.5D & 3.0D, ProNC or Galaad can be

used by exchanging the positioning control. Furthermore, various import

filters in format of *.plt (hpgl files), *.nc (DIN66025), *.ncp (zwichen),

*.t (mtasc), *.epj (editasc-project) ensure an universal data exchange.

|

|

General Technical Data |

|

Model |

ICP 2015 |

ICP 3020 |

ICP 4030 |

|

Machine dimensions |

535mm x 600mm x 690mm |

610 x 650 x 715 mm |

780 x 850 x 810mm |

|

Machine weight |

95 kg |

102 kg |

120 kg |

|

Milling table

dimensions |

400 x 250 mm |

500 x 250 mm |

600 x 375 mm |

|

XYZ-axis travels |

200mm x 150mm x 90mm |

300mm x 200mm x 90mm |

400mm x 300mm x 140mm |

|

Z-Axis head room |

100 mm |

115mm |

170mm |

|

Spindle motor

|

DC 500W |

|

Maximum speed

|

50mm/sec. |

|

Power supply |

110 to 230V , 50/60Hz |

|

Drive system |

16x10mm precision ball screw driven spindles

with linear slide bearing guides |

|

Stepper motor

|

Integrated 4-axis microstep stepper motor controller, RS

232 communication interface |

|

Operating software |

EdiTasc (realtime software)

for the parallel interface |

|

Dimensions

|

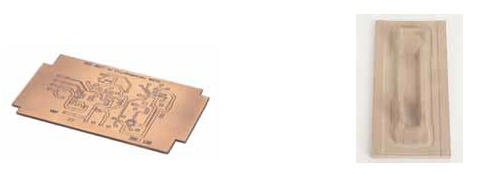

Applications

1. sign making

2. architecture model making

3. PCB outline milling

4. prototyping

5. schools / education

6. contour milling

7. pocket milling

8. 3D milling

9. jewellery market

10. cylindrical surface machining (optional

11. multi-side machining (optional)

|

Sign making

rotary machining

wax mould

PCB outline milling (isolation milling)

3D model |

Typical materials for machining |

Plastics

Aluminium

Wood

Brass

PCB material

Wax

|

|